We Make Wellington Boot for All

Customization & Manufacturing Services

OEM & ODM For B2B Orders.

Moderate price. On-time delivery.

365 days quality guarantee.

Love to see the proud shining on kids' faces after conquering a new puddle, AbsoluteWelly works hard to create an entirely different, one-of-a-kind way to manufacture better wellington boot for them.

We know what you're thinking now, how many ways could there be to manufacture wellington boot? Well, we bet there are at least two. What other suppliers do and what we do. And we guarantee once you get your first order made with AbsoluteWelly you will agree with us on "TWO WAYS".

---- AbsoluteWelly Team

Your Qualified Wellington Boot Manufacturer

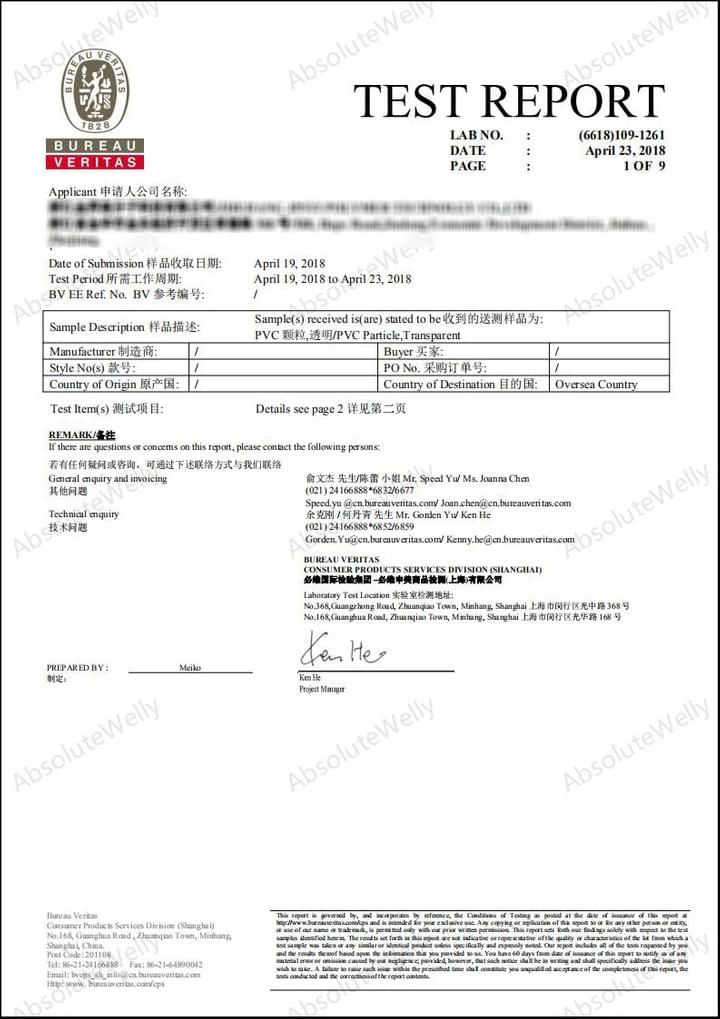

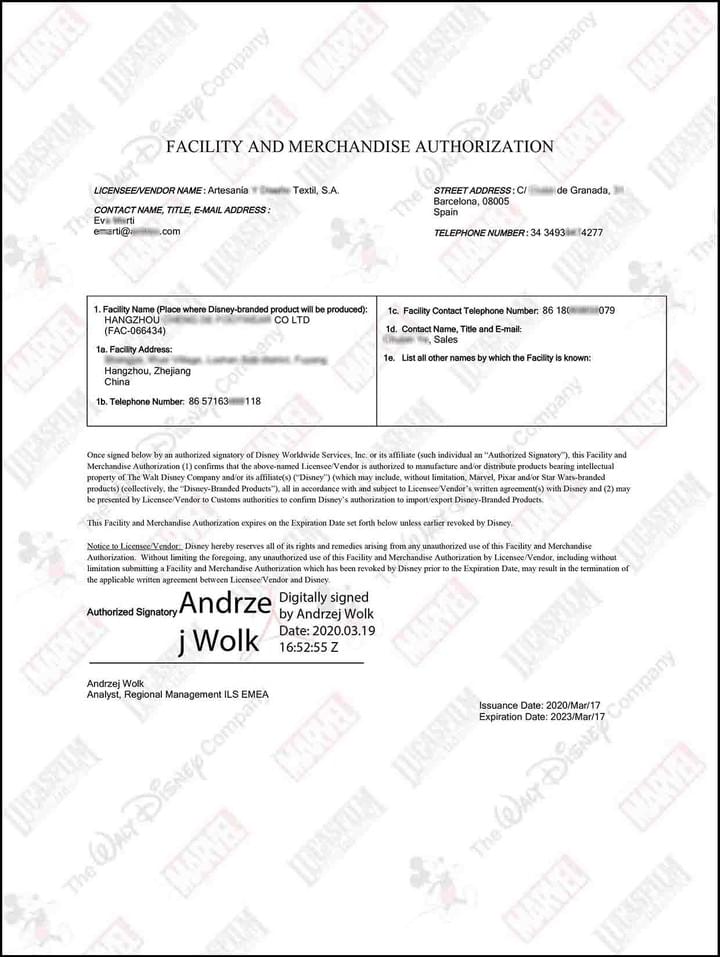

Test Report, BSCI Audit & Brand Authorization

Eco-friendly PVC Particle Test Report

BSCI Audit Report

Disney Authorization

Meet Our Wellington Boot Manufacturing Team

Every Pair Of Wellington Boots Is Crafted With Care

Upper Making

Sole Putting

Pressing

Quality Checking and Packing

We Do Wellington Boot OEM Very Well

At AbsoluteWelly, we believe that, for kids, wellington boot is not just for waterproof, it means more.

Kids are growing explorers, curiosity is such a treasure. In order to maximize their natural exploring time in childhood, wellington boot is absolutely necessary to cope with rain and snow. With wellington boot on feet, mud is funny, puddle is interesting, rain could be played with.

Therefore, each pair of wellington boot manufactured by AbsoluteWelly bears a belief:

For Kids & For Joy

With belief in mind, wellington boot manufacture at AbsoluteWelly is not a simply repeated job but a job with enthusiasm.

- QUALITY SHIPMENT IS A MISSION

- ON-TIME DLIVERY IS A RESPONSIBILITY

- MODERATE PRICE IS A PROMISE OF WIN-WIN SITUATION

- REFUND-AGREEMENT ON DEFECTIVE BOOTS IS A GUARANTEE

If you are also in kids wellington boot/rainwear business, AbsoluteWelly is willing to cooperate with full sincerity and honesty.

Our high demands on manufacturing aim to add value to your brand.

Find out our wellington boot styles below or learn more about AbsoluteWelly here.

Wellington Boot for Kids

cute rubber boots, light up wellies, neoprene wellies, warm toe wellies, all you need we will make

Classic Rubber

Wellington Boot Manufactured By AbsoluteWelly

Printing Rubber

Wellington Boot Manufactured By AbsoluteWelly

3D Character Rubber

Wellington Boot Manufactured By AbsoluteWelly

Neoprene Rubber

Wellington Boot Manufactured By AbsoluteWelly

Eco-Friendly PVC Solid Color Wellington Boot Manufactured By AbsoluteWelly

Eco-Friendly PVC Printed Lining Wellington Boot Manufactured By AbsoluteWelly

Eco-Friendly PVC Light-Up Wellington Boot Manufactured By AbsoluteWelly

Winter Warm Lining

Wellington Boot Manufactured By AbsoluteWelly

Wellington Boot for Ladies and Mens

A Typical Wellington Boot Manufacturing Day

- A typical wellington boot manufacturing day at AbsoluteWelly is from 8AM to 5PM.

- Prodution schedule is planned rationally in advance and carried out productively everyday. Work overtime is not a culture.

- Just in case our customers need help on an urgent shipment, all of our members will definitely do the best to catch the ETD.

- Besides holidays, some special days like "The Children's Day", all of our memebers also have a day off to enjoy with their kids.

When our wellington boot brings joy to kids overseas, we believe our members should have time to gather with their families too.

If you are looking for wellington boot manufacturers in China, AbsoluteWelly is your best choice. We work with Wellington Boot Company, Rubber Boots Manufacturer Abroad, Rainwear Manufacturer Overseas, Wholesale Rain Boots Distriutors, etc.

Send us inquiry and let us manufacture the best wellington boot for kids together.

AbsoluteWelly Always Treats Customers With

Sincerity & Honesty

YOUR #1 WELLINGTON BOOT SUPPLIER IN CHINA

Selling Wellington Boot Won't Be Easy If Customer Picked The Wrong Supplier.

AbsoluteWelly's Goal Is Simple:

With Our Effort On Every Detail From Sample Stage-Mass Production-Shipment-After Sale Service

We Want To See Our Wellington Boot Selling In Cusotmers' Store.

*Quality Shipment *On-time Delivery *Moderate Price *Refund Agreement

With all these promises, AbsoluteWelly aims to be your most reliable wellington boot supplier in China. Together, we bring more joy to kids and boom your business performance at the same time.

- For Importers and Wellington Boot Companies: AbsoluteWelly has rich experience in sample development. Experienced technician, skilled workers, good common sense, quick action and communication...all these will help to minimize your international purchasing cost.

- For someone new in wellington boot business : AbsoluteWelly is happy to recommend the best selling wellington boot in your local market and offer you more help in logistic service to make new business safe and easy.

- QUALITY IS OUR CULTURE. AbsoluteWelly always pay close attention to wellington boot quality. Just in case one or two pairs boots won't function well in our shipment, AbsoluteWelly guarantees each customer a Refund Agreement. Within exclusive 1 year quality guarantee (only 6 months by all other suppliers), AbsoluteWelly will take full responsibility of defective wellington boots and refund the money accordingly.

With AbsoluteWelly your money is safe, your wellington boot business is safe. Let AbsoluteWelly manufacture your wellington boot for kids.

You might also find the best supplier to customize wellington boots for your brand by a simple click here.

Start Working With AbsoluteWelly

Your Reliable Wellington Boot Manufacturer in China

Contact Us & Talk Further

TODAY!

SEND INQUIRY

We manufacture more joy for kids!

Frequently Asked Questions

Wellington boot or rain boots are quite popular all over the world. Started as a custom riding boot for one of the most famous military leaders in history, It has nw become a widely used item in every way of daily life: being an eye-catching fashion footwear for all walk; offering work protection for workers in wet, muddy and difficult conditions and even being an necessity for kids amusement---the endless fun in puddle jumping. Wellington boot is truly a good item for business. However, before importing wellington boot from China, here are 5 things you neeod to know.

1. What kind of wellington boot should I import?

- Well, according to the workmanship, there are 2 kinds of wellington boot: handmade rubber boots VS injection molded boots like PVC boots.

- Handmade rubber boots are made of natural rubber through the process of rubber refining, shaping, laminating and vulcanizing. Rubber boots are easy to shape and can be designed with various patterns. Besides printing, kids boots can also be made into vivid 3D characters. Because of handmade, no two pairs of rubber boots are alike! Therefore, uniqueness and diversity are the hallmarks of rubber boots.

- Injection molded boots are mechanical products, the raw materials used are traditionally PVC and EVA, but in recent years more and more thermoplastic material like TPR, TPE , TPU are used, which are recyclable, light-weight and economic. Due to the limitation of mold, PVC boots have a more permanent look but can still add character with printed lining and colorful glitter powder. Another eye-catching point is PVC light up boots for kids, where light is where laughter is.

2. Where should I import?

- Shoe industry is widely spread all over China. For wellington boot, the main production bases are Jiangsu, Zhejiang, Fujian, Guangdong, Shandong and Hebei.

- If you’re looking for handmade rubber boots for kids and ladies, Jiangsu and Zhejiang would be the right places. While manufacturers in Zhejiang make numerous rubber boots for European and American market, orders from Japan are usually fulfilled in Jiangsu area.

- Injection molded boots could be found easily in every area but if you’re looking for work boots, Zhejiang and Hebei are the industrial gathering places.

3. Who should I work with?

- Factory directly or trading company? It’s depending on several factors.

- In theory, working directly with the factory means lower prices because no middle man ever gets involved.But finding the right factory could be a time-consuming and laborious job. And if you're not familiar with the product process, it's hard to tell if the factory is right for you.

- By working with a trading company, you will gain easier communication and an overall solution/advice based on your sourcing requirements. Depending on their experience and knowledge of the local market, the trading company may also provide recommendations for hot items and advice on future trends, which will be an additional useful value.

4. What are the key points of quality?

- Since rubber boots are all handmade products, In the case of the same rubber formulary, the key point of quality lies in the delicacy of each step of the handmade process. A curved decoration line, a skewed patch, a stained logo, an uneven mudguard on left shoe and right shoe, a scratch on the vamp, etc, every little flaw lowers the class of rubber boots. The key to improving these problems is to choose quality-conscious factories and to reinforce product inspection.

- As for injection molded shoes, let's take PVC rain shoes as an example, the most important thing is whether the PVC particles used are eco-friendly. Plain PVC particles emit an odor, which worsens as the temperature rises. Then it comes to the trim of a finished boot. Whether the remnants of the injection port are trimmed cleanly, whether the fit of the logo and decoration patch are symmetrical to the right and left foot, whether the shoes are wiped clean and free of stains and fingerprints before they’re put into polybag - all these details are critical to the sales outcome.

5. When should I make a purchasing plan?

- The peak season for rain boots is in the second half of the year. In order to plan your purchases effectively, you need to know in advance how long the entire project will take.

- Samples usually take 10-15 days, while production takes 30-45 days. Considering supplier sourcing and sample revisions, it takes at least 1.5 months to confirm every detail before an order is placed. If shipping takes another 1 month, then the entire procurement project will take 3.5-4 months to effectively complete. Plan your purchases carefully so that you don't miss the sales season.

The "Hot-Paste Method" vs "Cold Paste Method"

Which Manufactures Better Wellington Boots ?

How to choose right supplier & right manufacturing method for your wellington boots orders?

1. Usually the rubber wellington boots are made of rubber as the main raw material, which can be composed of rubber materials, but also other materials such as cloth, leather as auxiliary materials and rubber material combination. In China, the domestic rubber wellington boots manufacturing process is composed of the following processes

mixing - natural rubber or synthetic rubber and other rubber raw materials in the rubber cutting machine into a certain weight requirements of the block, and then The plasticity of the rubber is about 0.4-0.5, then according to the needs of different occasions in the above-mentioned rubber mixed with various accelerators, antioxidants, fillers, enhancers, vulcanizing agents, coloring agents and other organic inorganic chemical raw materials, and mixed in the rubber refining machine into a uniform plasticity of 0.4-0.6 or so of the compounding rubber.

Film manufacture - The above-mentioned compounding rubber is then extruded into a certain thickness of rubber film by repeated rolling through the extruder.

Manufacture - The above-mentioned film of certain thickness is then rolled and cut into films of various shapes and sizes by rolling and cutting machine.

Forming - the various shapes and sizes of the film will be sent to the molding line, through the manufacture of molding workers, a variety of films according to different requirements on the shoe last with adhesive paste bonding each other into a raw rubber wellington boots.

Vulcanization - the above-mentioned raw rubber wellington boots and then put into the vulcanization chamber, under the action of a certain temperature, time, pressure three elements for vulcanization, so that it becomes a fixed shape, elasticity, strength, wear resistance.

2. The above technique is called "hot-fit". The above manufacturing process is called the "hot-paste" rubber wellington boots manufacturing process, which is characterized by the fact that the rubber material is not sufficiently cooled (i.e., still in a hot state) after being rolled and shaped into film by the roll cutting machine and then provided to the molding line for the molding of raw rubber wellington boots, so this "hot-paste" rubber wellington boots manufacturing process is often very difficult for the manufacture of raw rubber wellington boots. "

First of all, due to the continuity of the "hot-paste" process, the rubber film is not sufficiently cooled before being rolled and cut into film, because the raw rubber material changes from hot to cold state to shrink, and the shrinkage rate is quite large. Therefore, the actual size of the film cut into the last is larger than the size of the last, and the excess rubber must be trimmed when forming on the last, which will not only cause the difficulty of alignment, but also often cause the waste of rubber, and finally cause the error of product size and the decline of product quality, and the actual error is always between 2-4m/m.

Secondly, the adhesive material has certain stickiness in the hot state, and the surface of the film is often exposed to the air after rolling and cutting, so it is easy to be bruised, rubbed, and even adsorbed with dust and garbage on the adhesive surface, which becomes a kind of pollution and seriously affects the quality of the products.

Once again, the hot state film has a certain viscosity, and the manufacturing process of the "hot paste method" can only be rolled and cut layer by layer, forming a running operation, and also due to the slow speed and poor quality of the extruder's film, thus seriously affecting the process and quality of the later processes, such as to improve the output, it is necessary to extend the roll-cutting time, and also Since the molding process of rubber wellington boots requires careful trimming and alignment, all these will directly affect the number of shoes produced per unit time. The above "hot-paste method" process not only seriously affects the quality and quantity of products, but also has low work efficiency, high cost and generally poor economic efficiency.

3. In order to overcome the above-mentioned shortcomings, a "cold-paste" rubber wellington boots manufacturing process was invented to effectively improve the quantity of shoes produced per unit time and improve product quality.

4. The manufacturing process of the "cold-past method" is mainly divided into mixing, film, coating, cooling, manufacture, molding, vulcanization and other processes, which are described in detail below.

First, the mixing process will be a large block of natural rubber or synthetic rubber cut with a cutting machine for a certain weight of rubber blocks, the rubber blocks into the mixing machine (rubber refining machine) will be plasticized into a certain degree of plasticity spelling with rubber, in these spelling with rubber can be mixed with a variety of accelerators, antioxidants, fillers, enhancers, vulcanizing agents, coloring agents and other organic, inorganic chemical raw materials, and in the mixing It can be mixed with various organic and inorganic chemical materials such as accelerator, antioxidant, filler, reinforcing agent, vulcanizing agent, coloring agent, etc., and mixed in the mixing machine to become a uniform plasticity of about 0.4-0.6. Through the above ratio, it can achieve the performance of various kinds of compounding rubber, to meet the product's various use occasions and customer requirements The above process is basically the same as the existing technology "hot-paste method" manufacturing process.

Second, the film process through the mixing machine to mix a certain degree of plasticity of the compounding rubber. Then after calendering machine calendering will form a certain thickness of the film. This film can not only have a certain color, (because in the mixing to add the required coloring agent and have a certain color and luminosity), but also through the calendering and the formation of a variety of patterns, a variety of different types or colors, patterns of mixed rubber must be calendered separately to make the film. The said calender rollers using cooling water rollers, so that the temperature of the film calendered by the calender has dropped, to achieve the purpose of the initial cooling, favorable to the next process to improve efficiency. Of course, the above preliminary cooling can also be directly used to stack the natural cooling or a combination of the two ways.

Third, the coating cooling process in the above through the initial cooling of the surface of the rubber mold coated with a layer of hot melt isolating agent, the isolating agent is usually used in the melting point of 80-90 ℃ zinc stearate or aluminum stearate, due to the layer of isolating agent so that the film surface viscosity is covered, can be placed on top of each other, and has a certain role in protecting the surface of the film. This hot-melt barrier has a barrier effect in the cold state, and melts automatically when the temperature exceeds its melting point. Therefore, after the initial cooling of the previously described film coated with a layer of hot melt release agent, its use is more effective, but in general, if the film directly after calendering machine calendering temperature does not exceed the hot melting point of the release agent can be used directly to coat the process. The above process can also be directly used in the original technology of the extruder instead of the calender of the present invention, but the present invention uses the calender because of the high surface finish of the calender roller, and the calendering speed is faster than the extrusion speed, so the film preparation efficiency is high and the surface finish of the film is good. The film produced by the above process is then stacked and naturally cooled so that the shrinkage of the film is basically reduced to zero before it can be supplied to the next manufacturing process. Due to the different nature of various films (i.e., different ratios), the shrinkage of the film is determined by actual experience, generally after natural cooling to room temperature, and as the film temperature decreases, the shrinkage is gradually reduced.

5. The manufacturing process is carried out on the punching and cutting machine, which is generally equipped with various specially shaped punching knives on the upper part of the hydraulic machine. The multi-layer film of the same type, which is fully cooled and the shrinkage rate is basically reduced to zero, is placed under the hydraulic punching and cutting machine to become a multi-layer film with a certain shape that can be divided into several layers. As a result of the punching and cutting method, the number of films produced greatly exceeds the number of original manufacturing processes, so that the excess films can be put into the transit warehouse for backup, which solves the necking phenomenon of the original process in this process and greatly improves the output of products. Since the shrinkage rate of this multi-layer film is basically reduced to zero, the shape and size of the film are basically the same as those of the last, so there is no need for trimming and other work, which greatly improves the quality and standardization of the product and reduces the cost.

6. Therefore, the film or other auxiliary materials required for each part of the shoe are laminated on the last with lining and pulp, and the film and film of each part and other auxiliary materials are laminated with pulp. Bonding molding. This glue paste is generally modulated by the manufacturer itself, with natural rubber or latex as the main raw material, or commercially available "neoprene" can be used as a substitute.

7. Six vulcanization process of this raw rubber wellington boots must be vulcanized in order to become a finished product, the molding of raw rubber wellington boots will be placed into a special vulcanization room, under the action of certain temperature, time and pressure three elements of vulcanization, so that the internal chemical structure of the fundamental changes, become a fixed shape, with a certain strength, elasticity, wear resistance of shaped products, general vulcanization temperature at 125-135 ℃, the pressure is 2.8-3.5kg/cm2, time in 50-60 minutes, because the surface of raw rubber wellington boots also has a residual hot melt isolate, this isolate in the above-mentioned vulcanization temperature will quickly melt away, and finally get the product with a clean and bright surface. The manufacturing process of the above-mentioned rubber wellington boots is called the cold-paste method in comparison with the prior art.

8. The "cold paste method" is an improvement to the "hot paste method". It not only retains some features of the existing process, but also corrects the necking process which affects the quality and quantity of the product, thus greatly improving the quality of the product and the standardization procedure, increasing the quantity of the product formed per unit time, reducing the cost, and making the economic efficiency of the enterprise significantly improved.

© 2023 Nanjing Lefun Outdoor Products Company Limited